End Mill Tungsten Carbide Ball Milling Cutter Cutting Tool

Product Description

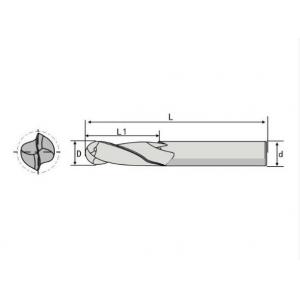

D=diameter * H=blade length * d=shank length * L=overall length

Spuer Particle Tungsten steel coating 2Flute ball mill(Standard length type,Extended Type) | D | d | L1 | L |

| R0.5 | 4 | 2 | 50 |

| R1 | 4 | 4 | 50 |

| R1.5 | 4 | 6 | 50 |

| R1.5 General | 3 | 6 | 50 |

| R2 | 4 | 8 | 50 |

| R2 Extended type | 4 | 8 | 75 |

| R2 Extended type | 4 | 8 | 100 |

| R2.5 | 6 | 10 | 50 |

| R3 | 6 | 12 | 50 |

| R3 Extended type | 6 | 12 | 75 |

| R3 Extended type | 6 | 12 | 100 |

| R4 | 8 | 16 | 60 |

| R4Extended type | 8 | 16 | 75 |

| R4Extended type | 8 | 16 | 100 |

| R5 | 10 | 20 | 75 |

| R5 Extended type | 10 | 20 | 100 |

| R6 | 12 | 24 | 75 |

| R6 Extended type | 12 | 24 | 100 |

| R8 | 16 | 32 | 100 |

| R10 | 20 | 40 | 100 |

Product detail display:

Characteristic:

*Using high quality new edge, smooth surface, the edge of the special fine grinding wheel grinding, 200 times larger than the lack of micro, the coating has better corrosion resistance!

*Ultrafine tungsten steel base material with high strength and abrasion resistance, can be of 50° below the material heat treatment direct rough processing and fine processing.

*Two edge milling cutter is mainly based on the groove milling pin,

*Tolerance in 0-0.02 negative rake angle design, taking into account the edge strength and sharpness, with large core design, enhanced tool steel, cut the pin and the pin is more stable, reduce the tool change times, improve the machine moving rate, save the production process.

*Cutting edge angle to take the latest technology, strict scientific groove design, making the tool wear resistance and cutting strength to get a perfect combination.